Statistical Process Control Software

What is SPC?

Statistical Process Control (SPC) is a crucial method in quality control, extensively used across various industries, especially in manufacturing. SPC is a systematic, data-driven approach that employs statistical methods to monitor, control, and enhance processes and their performance.

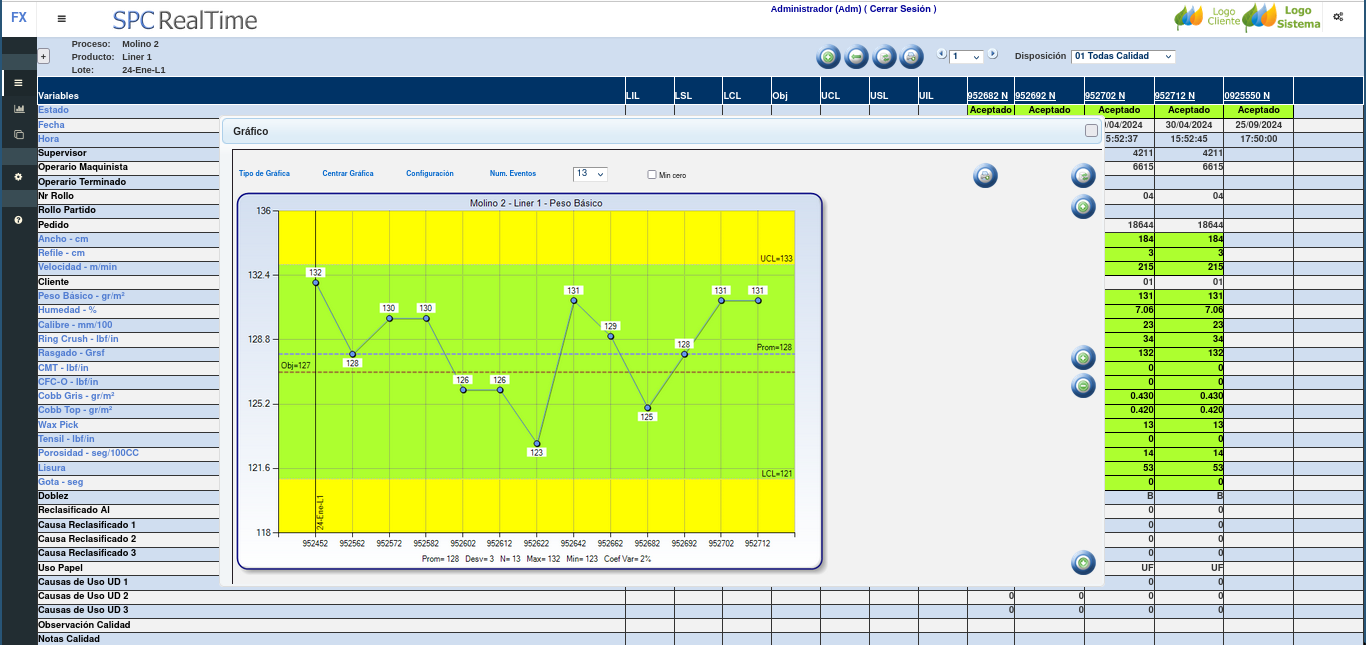

SPC relies heavily on data to evaluate process performance. By directly collecting data from the production line and analyzing it throughout different stages of the manufacturing process, our SPC Software empowers plant teams to identify trends, patterns, and anomalies. This approach enables informed and timely decision-making, eliminating reliance on assumptions or estimations.

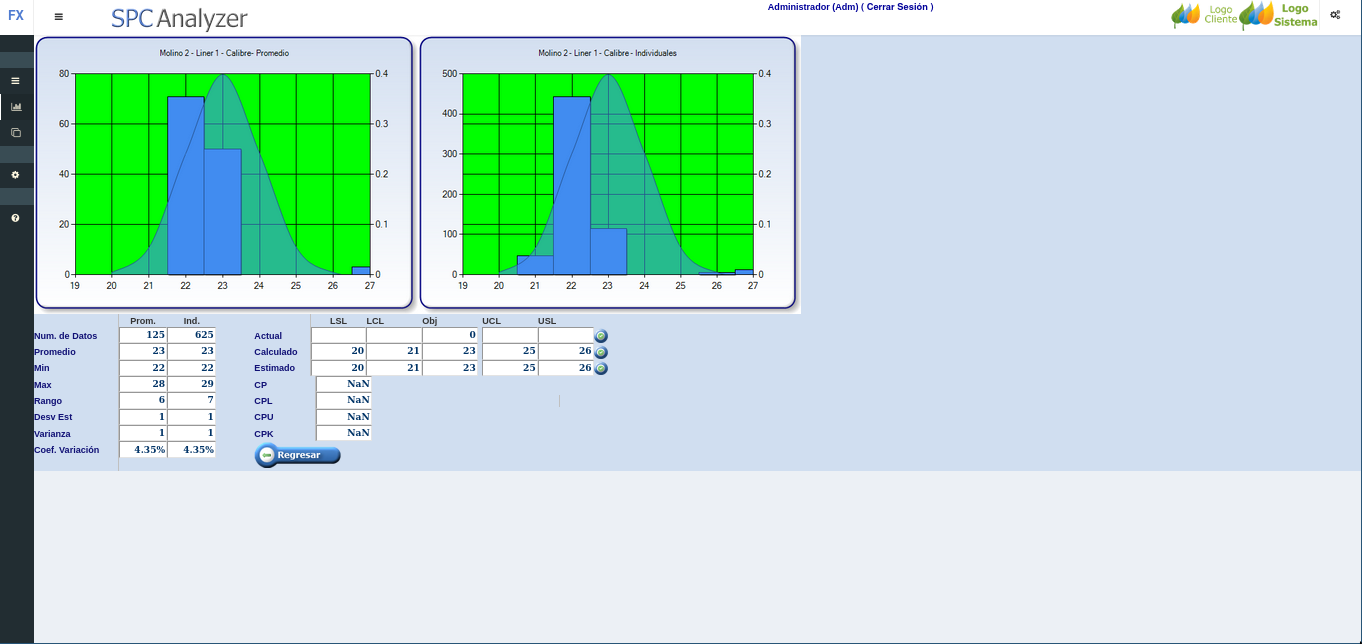

Variability is inherent in all industrial processes, particularly in manufacturing. However, excessive variability can lead to defects, inefficiencies, and diminished product quality. The primary objective of SPC is to detect and minimize process variability. By understanding and controlling this variability, manufacturers can consistently produce items within the desired specifications. SPC involves the continuous monitoring of processes to quickly identify deviations from the norm. This systematic approach ensures that issues are detected early and can be addressed before causing significant quality problems or production waste.

How SPC Benefits You

Our SPC software allows you to input specification limits for each variable in your products and processes. During production, the software records data for these variables and provides a visual comparison of actual data against the specification limits. This enables operators to easily see how the process is performing. If a special cause variation occurs, the software immediately alerts the operator to investigate and potentially correct the issue.

With real-time capabilities, our software provides critical information to various plant users, from production to maintenance and quality, enabling informed decisions about a product or equipment line.

The software’s comprehensive historical data processing tools and reporting allow you to update specifications and standards, solidifying process improvements.

Our SPC software is an excellent tool for enhancing data exchange with customers and suppliers regarding product specifications. It generates instant reports that can be customized to meet each company’s specific needs.